AMIT ENGINEERING WORKS

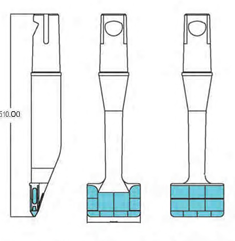

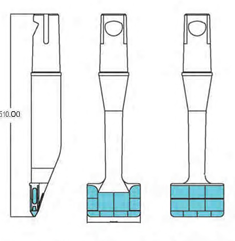

tungstene carbide tamping tools

your partner

We Have A Wide Range Of Tamping Tools Which Are Used In Railways As Railway Components. They Are Made Of High Quality Raw Materials & Covered All Sides By Tungsten Carbide Plates. The Use Of Alloys In Manufacturing These Tamping Tools Enables The Product To Give A Flawless Performance And Flexibility.

AEW Tungsten Carbide Tamping Tools (TCTI) Meets And Also Exceed The Specifications Laid Out By ROSO, Since It Offers High-strength-alloy Forged Shanks, CNC-produced Matching Fitting Surfaces, Full Tungsten Carbide Cover• age Of The Pad And Wear Areas Due To Its Slim, Insertion Friendly Profile.

• Increases life up to 15 times